Apart from certain printing processes, the principle of subtractive colour mixture is applied in all modern colour films and in most colour printing materials ( see: chromogenic process).

Although overlapping of the yellow, magenta and cyan filters (or the corresponding layers of the colour material) does not produce a complete black, because of the previously mentioned incomplete absorption of the light, "black" is nevertheless a relative impression, because even parts of the image which only allow a small amount of light through can appear black compared with other lighter areas. This fact makes it possible to use three-layer colour materials with the colours yellow, magenta and cyan.

The principle of subtractive colour mixture is also applied in modern-day colour negative films and colour slide films, which have, after exposure and processing, yellow, magenta and cyan dye layers on top of one another in the photosensitive emulsion layers. Only by combining these three subtractive colours (each with different intensity) is it possible to reproduce all the colours of the visible spectral range with three dye layers on top of one another.

Correction filtering by the subtractive method is done with colour filters having the mixed colours of yellow, magenta and cyan. Only with these colours is it possible to produce all the other mixed colours. In the absence of all three filters, we get white, and in the presence of all three filters, we get grey, because the technical dyes in the filters (like the developed emulsion dyes in the colour film) do not completely absorb the light passing through them. If they did absorb the light completely, the result would be black. For this reason, only one or two different filter colours are used for subtractive colour filtering. The combination of three filter colours is not recommended, because the grey resulting from the third filter colour would lengthen the exposure time unnecessarily.

The subtractive colours yellow, magenta and cyan are mixed colours. They are formed when white light passes through yellow, magenta and cyan filters, or when white light is reflected on the opaque surface of yellow, magenta or cyan objects. A yellow filter absorbs the blue spectral components of white light, and only lets the green and red spectral components pass through. The green and red rays of light combine to produce the mixed colour yellow. In the same way, a magenta filter absorbs green and allows only blue and red (see: magenta) through, while a cyan filter absorbs red and allows blue and green light through. This means that colour filters and coloured objects either reflect or allow through the rays of light which correspond to their inherent colour.

Status densitometry thus distinguishes between the evaluation of colour negative and colour reversal film on the one hand and colour printing materials on the other. It produces in colour density data and colour density curves, which correspond to the characteristics of the respective material.

Status M densitometry (with Status MM filters) is used for densitometric colour density measurements of colour negative films. What is measured here is the printing density, corresponding to the matching of colour negative films to the spectral sensitivity of the subsequent printing material.

Status A and D densitometry is used for the measurement of films and printing materials for visual observation. What is measured is therefore the visual optical density.

Status D densitometry is used for the measurement of non-transparent printing materials, and also utilizes Status AA filters.

Status A densitometry (using status AA filters) is intended for the measurement of colour reversal film. Status AA filters have a particularly narrow spectral transmittance in the blue and green spectral ranges.

In contrast to the spectral analytical densities of individual emulsions calculated by the manufacturer, the user can obtain the integral colour densities by carrying out a densitometric measurement of the complete emulsion structure of colour materials (e. g. of control strips for process monitoring). By measuring the three subtractive emulsion dyes yellow, magenta and cyan under blue, green and red optical filters (in accordance with the spectral sensitivity of the emulsion layers), it is possible to find the colour densities of the emulsion dyes.

Status filters are light filters for the densitometric measurement of the integral colour densities of colour materials. They have particularly narrow spectral transmittance for the standardized light source of the densitometer, and are used among other things for plotting colour density and gradation curves.

Fig. : Determining the relative speed using the speed criterion.

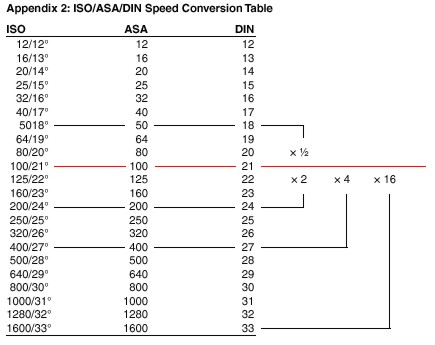

The speed criterion can be used in combination with the density curves in the AGFA Technical Data brochures to approximately verify the given film speed. If, for example, we plot the point of the speed criterion (0.1 above minimum density) on the density curve for AGFAPAN APX 25 (see also Technical Data Sheet APX 25) and, if we drop down vertically from this point onto the exposure axis, we obtain the logarithmic value –1.5. If we then leave out the minus sign and the decimal point, we get the DIN speed (15 DIN = ISO 25/15° with the APX 25).

According to DIN 4512, the speed criterion is a value on the density curve which, in black-and-white films for normal exposure conditions, corresponds to a density of 0.1 above minimum density. The resultant value on the x-axis represents the relative speed (see: DIN, ASA and ISO speeds).

Film materials have different speed ratings (see :DIN, ASA and ISO speed; see : spectral sensitivity).

The speed (sensitivity) is the ability of a photosensitive emulsion to change a given exposure by means of processing into a black or colour density corresponding to the exposure intensity. This property is also known as the “general sensitivity” or “photosensitivity”. It is achieved during production by special ripening of the emulsion (chemical sensitisation). Under the influence of added gold and sulphur compounds, so-called ripening nuclei form on the surface of the silver halide crystal, and determine the general speed of the photographic material (see: sensitisation).

Photography - Minilabs - Photo processing

Technical Documents - Documentos Técnicos: Technical Photographic Terms

Technical Documents - Documentos Técnicos: Technical Photographic Terms

Омисион: Таблица Asa Вшт >>>>> Download Now

ОтветитьУдалить>>>>> Download Full

Омисион: Таблица Asa Вшт >>>>> Download LINK

>>>>> Download Now

Омисион: Таблица Asa Вшт >>>>> Download Full

>>>>> Download LINK 9B